Why Custom OEM / ODM Solar Mounting Solutions Reduce Overall Project Cost

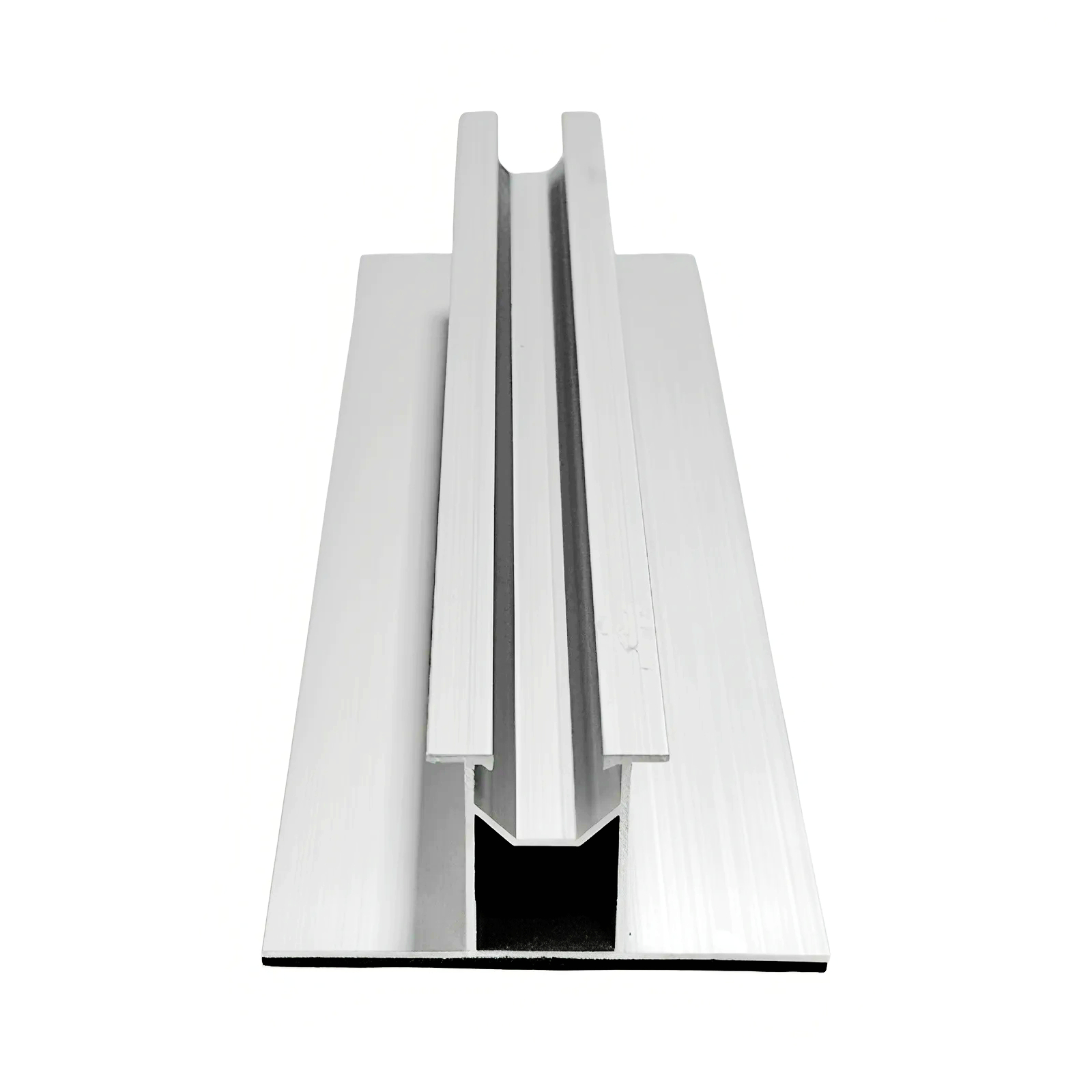

Custom OEM / ODM solar mounting solutions have become a preferred choice for EPC contractors, developers, and distributors seeking smarter, more cost-efficient photovoltaic (PV) project execution. Unlike standard mounting systems, custom-designed solutions are tailored to meet the precise needs of the project—roof structure, site conditions, module layout, engineering requirements, and installation preferences. This level of customization not only enhances performance and safety but also significantly reduces the overall cost of a solar power project. From material optimization to lower labor expenses, OEM/ODM manufacturing plays a key role in maximizing value. One of the most important ways custom solutions reduce project cost is through optimized material usage. Standard mounting systems are typically designed to cover a wide range of scenarios, which can lead to unnecessary material consumption. Customized OEM/ODM brackets, rails, and clamps, however, are engineered specifically for the project’s load calculations and structural conditions. This precision ensures that installers receive the exact components required—no excess, no waste. By reducing material weight while maintaining strength, custom designs help lower transportation, packing, and on-site handling expenses.

Custom OEM/ODM solutions also reduce installation time, which directly translates to lower labor costs. When a system is manufactured according to the project’s layout and roof or ground conditions, installers spend far less time adjusting components or modifying the structure during assembly. The parts fit perfectly, the layout is clear, and the installation sequence is straightforward. For large-scale projects, even a small reduction in installation hours per kilowatt can result in significant savings. Alliance Solar’s precision engineering and pre-assembled parts further streamline the installation process, helping EPC teams complete projects faster and with fewer errors. Reducing structural modifications is another major cost-saving advantage. Many commercial or industrial rooftops have unique layouts, obstacles, or load limitations. A standard mounting system may require additional reinforcement or even roof alteration to achieve proper support. Customized OEM/ODM systems eliminate this issue by being designed around the building’s existing conditions. By using adjustable brackets, optimized roof hooks, or specially engineered rails, the mounting system adapts to the structure—not the other way around. This helps avoid costly structural work and reduces long-term risk related to water leakage or roof damage.

Logistical efficiency is another important contributor to cost reduction. When components are produced specifically for a project, they can be packaged according to the installation sequence, building layout, and shipment strategy. This prevents confusion at the job site and reduces the time needed for sorting and handling materials. More importantly, custom production ensures that parts arrive in the right quantities, avoiding the need for emergency replacements or additional shipments. By optimizing logistics and reducing site delays, OEM/ODM solutions help keep projects on schedule and within budget. Custom-designed mounting systems also enhance long-term system reliability, which lowers maintenance and operational costs. A mounting structure built to match the exact environmental conditions—wind zones, snow load, seismic activity, or corrosion exposure—helps ensure decades of stable operation with minimal maintenance. High-quality materials, such as anodized aluminum or hot-dip galvanized steel, prevent structural deterioration, while precision manufacturing ensures secure panel placement. When the mounting structure performs reliably over 20–25 years, project owners avoid expensive repairs, component replacements, or downtime-related losses.

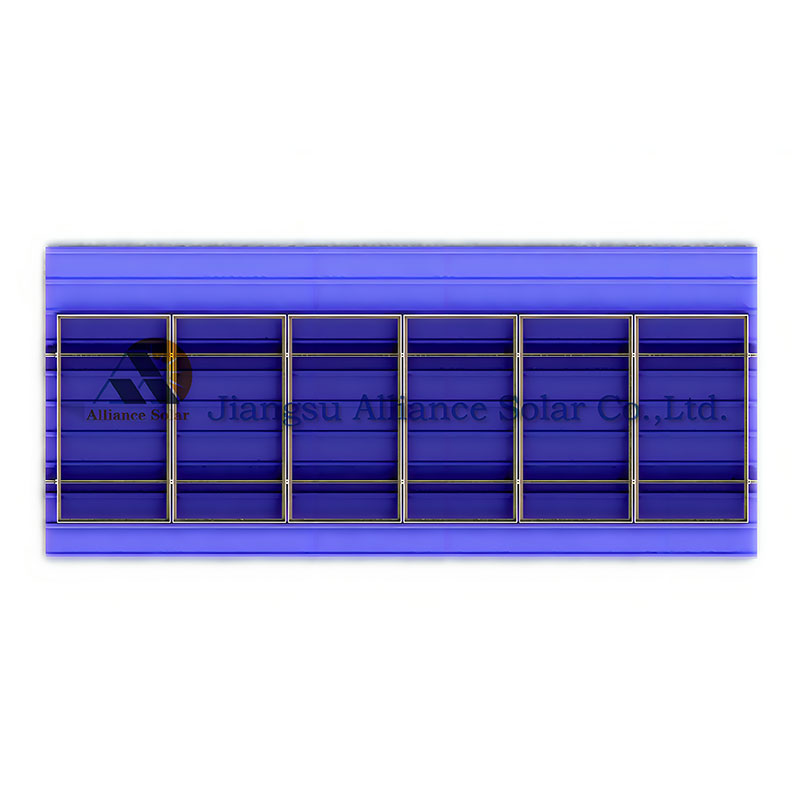

Another hidden advantage involves compatibility with different panel sizes and technologies. Solar panels are rapidly evolving, with new module dimensions and frame designs appearing every year. Custom OEM/ODM mounting systems ensure perfect compatibility with the panels chosen for the project. This eliminates issues such as misaligned clamps, improper pressure distribution, or the need for extra adaptors. A well-fitted mounting system protects panels from micro-cracks and frame stress, preserving energy production and preventing early module failure. The result is a more efficient and cost-stable solar asset over its lifetime. For distributors and large buyers, custom OEM/ODM solutions offer significant inventory advantages. Instead of stocking many different mounting components for various projects, a customized system allows buyers to receive exactly what they need, when they need it. This reduces warehouse costs, avoids product obsolescence, and improves cash flow. Alliance Solar’s flexible production lines make it possible to deliver tailored orders quickly, supporting global customers with rapid response and scalable manufacturing capacity.

In conclusion, custom OEM / ODM solar mounting solutions do far more than improve system design—they directly reduce overall project cost. By minimizing material waste, simplifying installation, lowering labor requirements, eliminating structural modifications, optimizing logistics, and ensuring long-term reliability, customized solutions provide a strategic advantage for modern solar projects. With Alliance Solar’s engineering expertise, advanced production capabilities, and commitment to global quality standards, customers can confidently achieve greater efficiency, stronger performance, and lower total project costs. Customization is not just a value-added service—it is a smart investment in the future of solar energy.

English

English