Understanding Load Capacity: How Our Mounting Systems Withstand Extreme Weather

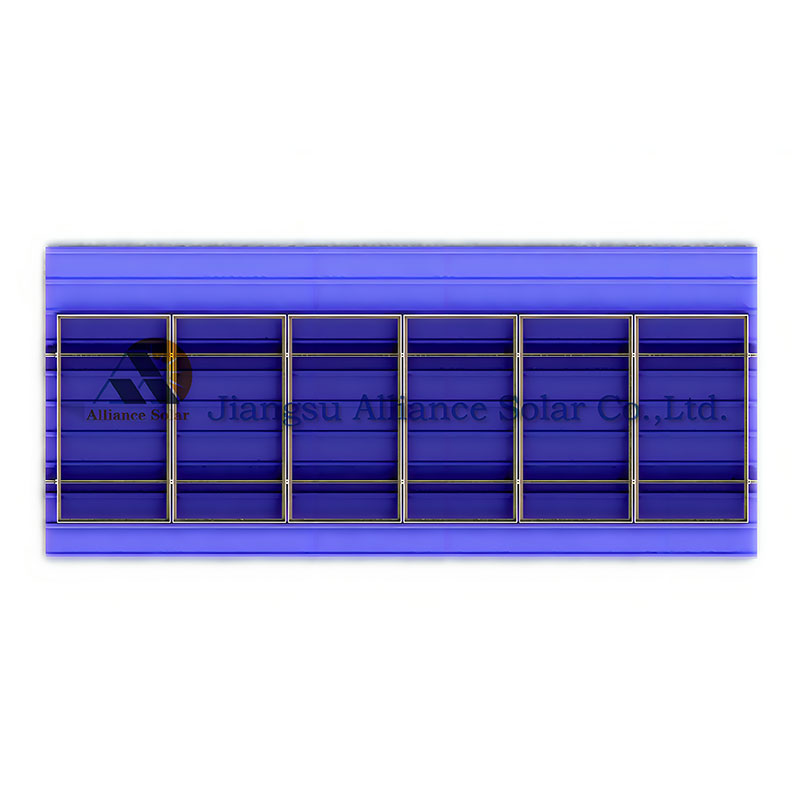

Understanding load capacity is a critical aspect of solar mounting system design, especially as photovoltaic installations are increasingly deployed in regions exposed to extreme weather conditions. Strong winds, heavy snow, seismic activity, and temperature fluctuations place continuous stress on solar structures throughout their service life. A well-engineered mounting system must not only support the weight of solar panels but also resist dynamic environmental forces without deformation or failure. At Alliance Solar, load capacity is treated as a core engineering priority, ensuring that every mounting system delivers long-term stability, safety, and performance even in the harshest climates. The foundation of reliable load capacity begins with accurate engineering calculations. Before any product is manufactured, Alliance Solar’s engineering team evaluates regional climate data, including wind speed zones, snow load requirements, and seismic conditions. These factors are combined with roof or ground structural data to calculate precise load-bearing requirements. Using proven engineering models and international design standards, mounting systems are designed to distribute forces evenly across the structure. This approach prevents stress concentration at connection points and ensures that the entire system works as a unified, stable framework.

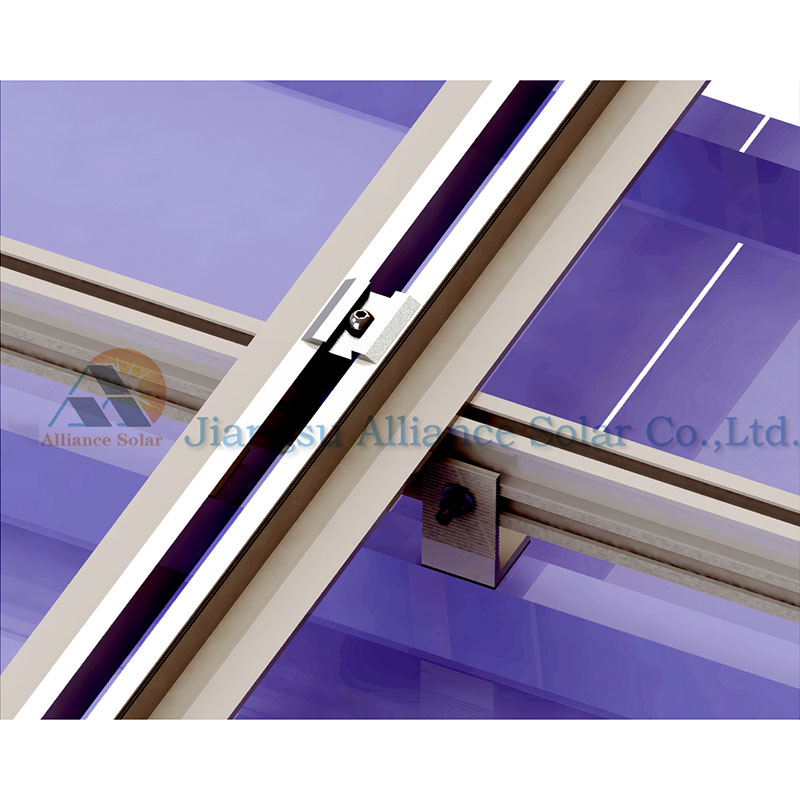

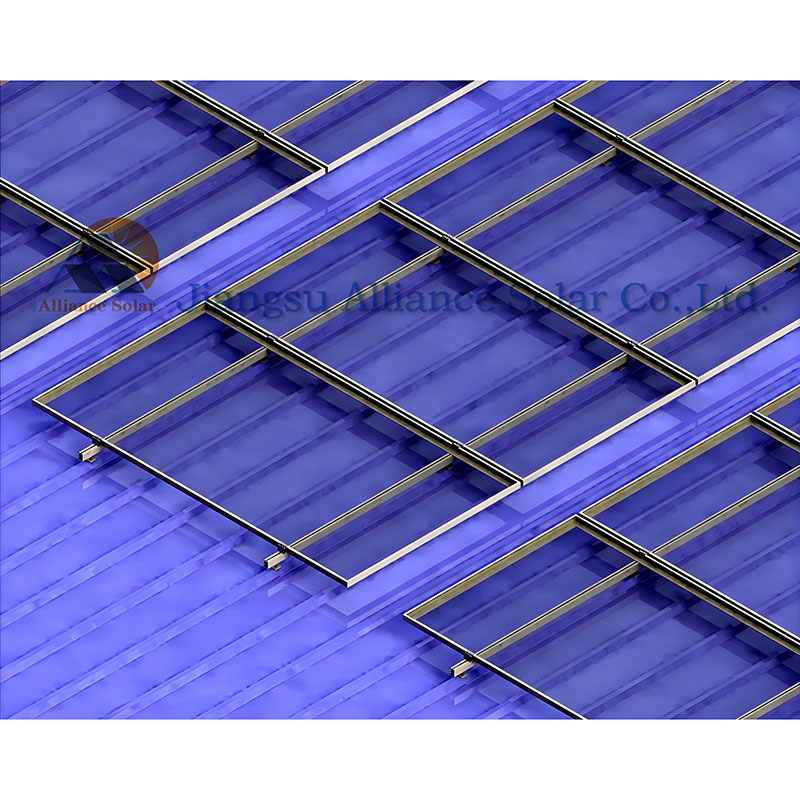

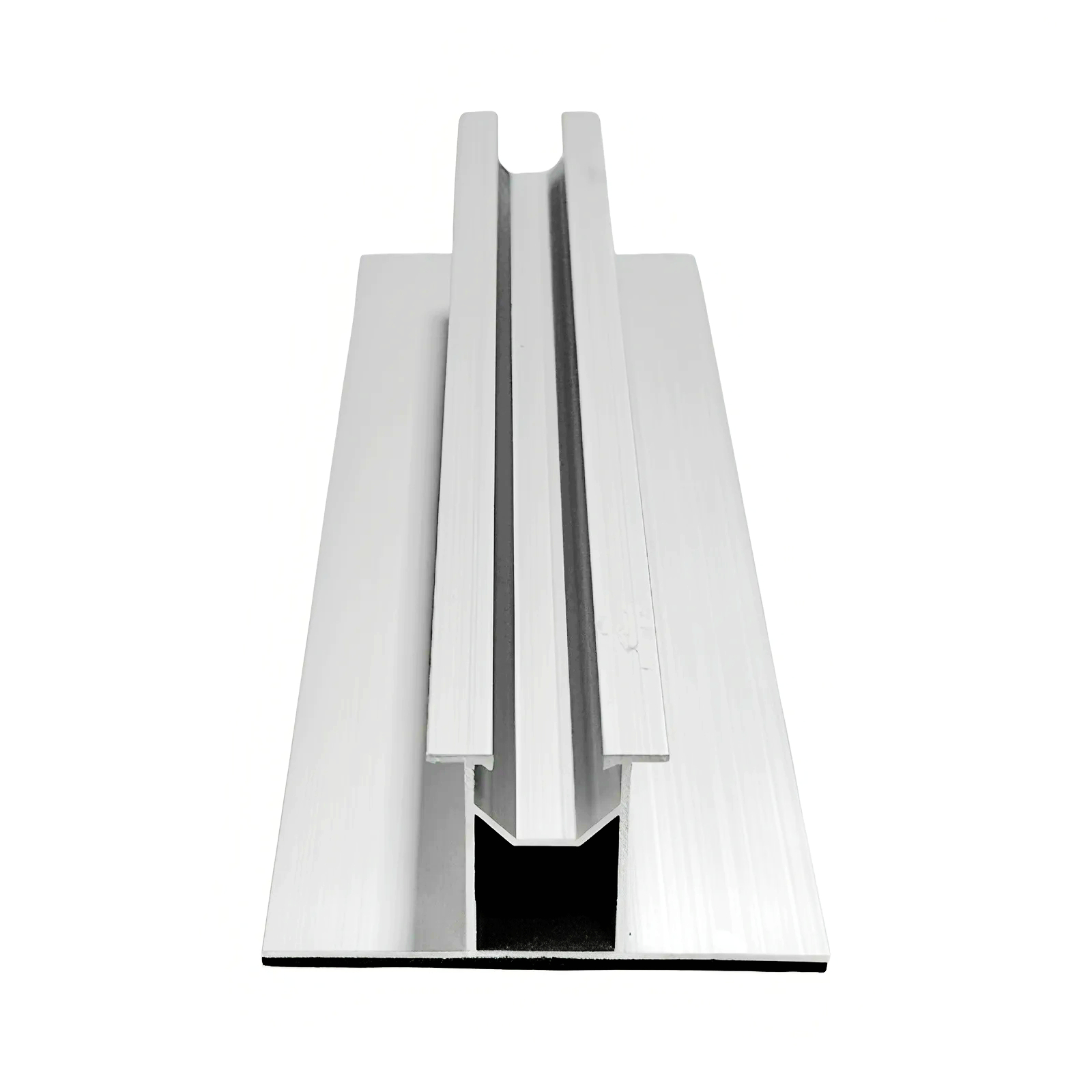

Material strength plays a decisive role in withstanding extreme weather. Alliance Solar carefully selects high-grade aluminum alloys and hot-dip galvanized steel known for their excellent mechanical properties. Aluminum provides a strong yet lightweight solution that reduces overall system load while maintaining high tensile strength. Galvanized steel offers superior rigidity and impact resistance, making it ideal for high-load ground-mounted systems or regions with heavy snowfall. Consistent material quality ensures predictable performance under extreme stress, allowing mounting systems to retain their structural integrity over decades of operation. Structural design optimization is another key factor in improving load resistance. Alliance Solar’s mounting systems are engineered with reinforced connection points, optimized cross-sections, and strategically placed support members. These design elements enhance resistance to uplift forces caused by strong winds and downward pressure from snow accumulation. Adjustable tilt angles and aerodynamic layouts also help reduce wind resistance by allowing air to flow smoothly around the panels. By optimizing geometry and load paths, the mounting system maintains stability even during severe weather events.

Precision manufacturing ensures that design calculations are accurately translated into real-world performance. Alliance Solar operates advanced production lines with CNC machining and precision forming equipment to maintain strict dimensional tolerances. Accurate component dimensions ensure tight connections and consistent load transfer across the entire structure. Even small deviations in hole placement or bracket alignment can weaken load performance, which is why strict quality control measures are applied at every production stage. This manufacturing accuracy ensures that mounting systems perform exactly as engineered when subjected to extreme conditions. Rigorous testing and quality verification further validate load capacity. Alliance Solar conducts mechanical strength tests, connection load tests, and surface treatment inspections to confirm that components meet or exceed design requirements. Products are developed and manufactured in compliance with ISO9001 quality standards and TUV certification requirements. These tests simulate real-world environmental stresses, providing confidence that the mounting systems can withstand long-term exposure to extreme weather without failure or excessive deformation.

Installation accuracy also plays an important role in achieving full load capacity. Even the strongest mounting system can underperform if installed incorrectly. Alliance Solar designs its systems for fast, clear, and error-free installation, with standardized components and detailed technical guidance. Clear installation instructions, pre-engineered layouts, and compatible fasteners ensure that installers can achieve the intended load performance on-site. Proper installation ensures that calculated load capacity is fully realized in real-world applications. Adaptability to different environments further strengthens system resilience. Alliance Solar offers customized OEM and ODM mounting solutions designed for specific climate challenges, such as high-wind coastal regions, snow-heavy northern zones, or seismic-prone areas. By tailoring design parameters, material thickness, and structural layout to local conditions, each system is optimized to handle the unique forces it will face. This customization helps reduce risk while maintaining cost efficiency and long-term reliability.

In conclusion, understanding and engineering load capacity is essential for building solar mounting systems that can withstand extreme weather. Through precise calculations, high-strength materials, optimized structural design, precision manufacturing, rigorous testing, and proper installation support, Alliance Solar delivers mounting systems that perform reliably in demanding environments. This commitment to load capacity and safety ensures stable operation, protects valuable solar assets, and supports long-term energy generation across global markets, even under the most challenging weather conditions.

English

English