Top Features to Look for in Modern Solar Mounting Structures

Modern solar mounting structures are a critical foundation of any photovoltaic (PV) system, directly influencing installation efficiency, system safety, and long-term energy performance. As solar projects continue to scale globally—across rooftops, ground-mounted arrays, and complex terrains—the demand for advanced, reliable, and cost-effective mounting solutions has never been higher. Choosing the right mounting structure requires more than basic strength; it requires smart design, durability, adaptability, and compliance with international standards. Understanding the key features of modern solar mounting structures helps developers, EPC contractors, and system owners build long-lasting and high-performing solar projects. One of the most important features to look for is structural strength and load-bearing capacity. Modern solar mounting systems must be engineered to withstand wind pressure, snow loads, seismic activity, and long-term mechanical stress. High-quality structures are designed using precise load calculations that meet regional and international building codes. Whether installed on rooftops or open ground, the mounting structure should maintain panel alignment and stability under extreme weather conditions. Reliable strength ensures not only system safety but also consistent energy output over the entire lifespan of the solar installation.

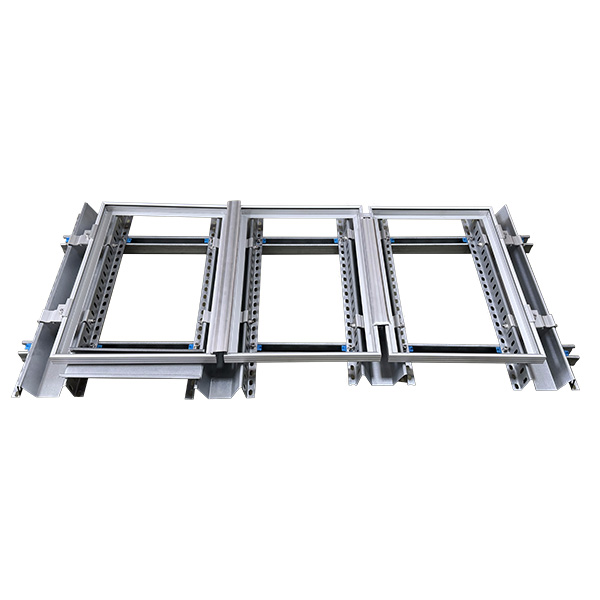

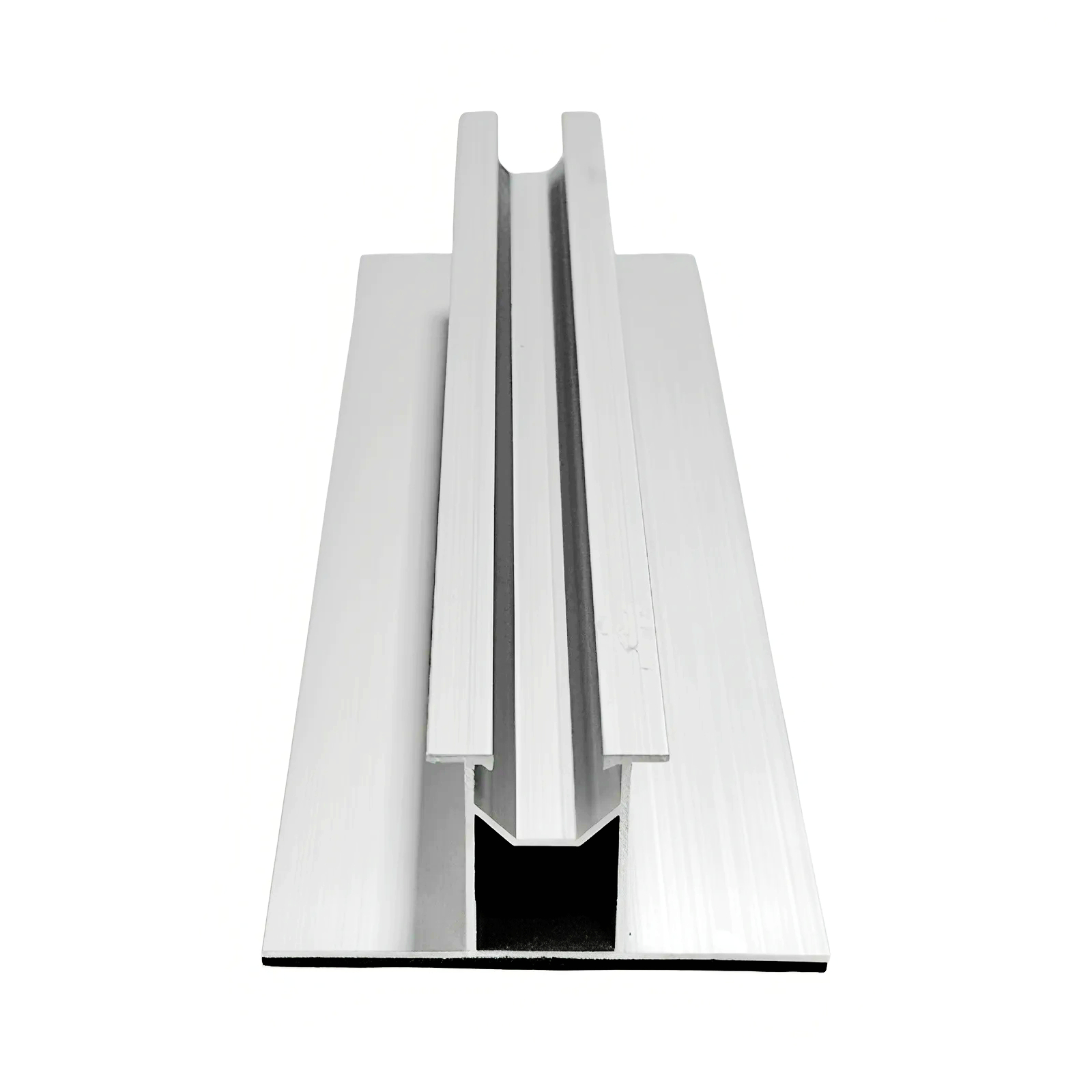

Material quality and corrosion resistance are equally critical in modern mounting systems. Solar power stations are expected to operate for 25 years or more, often in challenging environments such as coastal regions, deserts, or industrial zones. High-grade aluminum alloys and hot-dip galvanized steel are commonly used for their excellent strength-to-weight ratio and long-term corrosion protection. Advanced surface treatments, such as anodizing or zinc coating, further enhance durability. Selecting corrosion-resistant materials reduces maintenance requirements and prevents structural degradation that could compromise system stability. Another essential feature is fast and installer-friendly design. Modern solar mounting structures are increasingly engineered for quick and easy installation, reducing labor time and overall project cost. Pre-assembled components, standardized fasteners, and modular rail systems allow installers to work efficiently with fewer tools and minimal on-site adjustments. A well-designed mounting system not only speeds up installation but also reduces the risk of human error, ensuring consistent quality across large-scale projects.

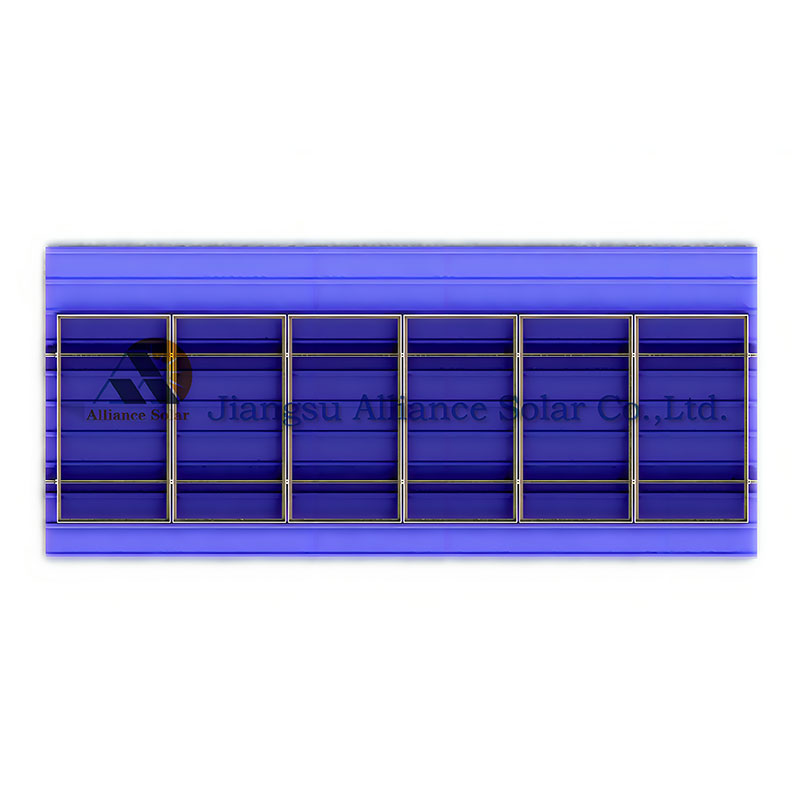

Flexibility and adaptability are also key characteristics of advanced mounting solutions. Every solar project is unique, with different roof types, terrains, and layout requirements. Modern mounting structures should support various installation scenarios, including metal roofs, tile roofs, flat roofs, and uneven ground. Adjustable brackets, multi-angle supports, and modular components allow systems to adapt without compromising structural integrity. This flexibility ensures that mounting structures can meet diverse project needs while maintaining safety and performance standards. Compatibility with a wide range of solar panels is another important consideration. As panel sizes, frame designs, and technologies evolve, mounting structures must accommodate these variations. High-quality systems are designed with adjustable clamps and precision-engineered interfaces that securely hold different module types without damaging the panel frame or glass. Proper compatibility ensures even pressure distribution and allows for thermal expansion, protecting panels from stress-related damage over time.

Safety and compliance with international certifications are also top features to look for. Modern solar mounting structures should meet recognized standards such as ISO9001 and TUV certifications, ensuring they comply with mechanical, safety, and quality requirements. Certified products provide confidence to project owners and investors, especially for international installations where regulatory compliance is essential. Safety-focused designs also protect installers during construction and reduce risks throughout the operational life of the solar system. Long-term reliability and low maintenance requirements further define high-quality mounting systems. Well-engineered structures maintain their mechanical strength and alignment over decades, reducing the need for frequent inspections or repairs. Durable fasteners, secure locking mechanisms, and stable connections help prevent loosening caused by vibration or thermal cycling. By minimizing maintenance, modern mounting structures help lower long-term operational costs and improve the return on investment.

Finally, customization and OEM/ODM capability have become increasingly valuable features in modern solar mounting structures. Custom-designed systems can be tailored to project-specific requirements, including local climate conditions, building constraints, and installation preferences. OEM and ODM solutions allow manufacturers to optimize materials, design, and logistics for each project, improving efficiency and reducing overall cost. This level of customization ensures that the mounting structure delivers maximum value throughout the project lifecycle. In conclusion, modern solar mounting structures are far more than simple support frames—they are engineered systems that directly affect performance, safety, and longevity. Key features such as structural strength, corrosion resistance, fast installation, adaptability, panel compatibility, certified safety, long-term reliability, and customization define the quality of a mounting solution. By choosing advanced mounting structures designed to meet today’s technical and environmental challenges, solar developers can ensure stable operation, efficient installation, and long-term success for their photovoltaic projects.

English

English