How We Maintain Industry-Leading Engineering Accuracy in Solar Mounting

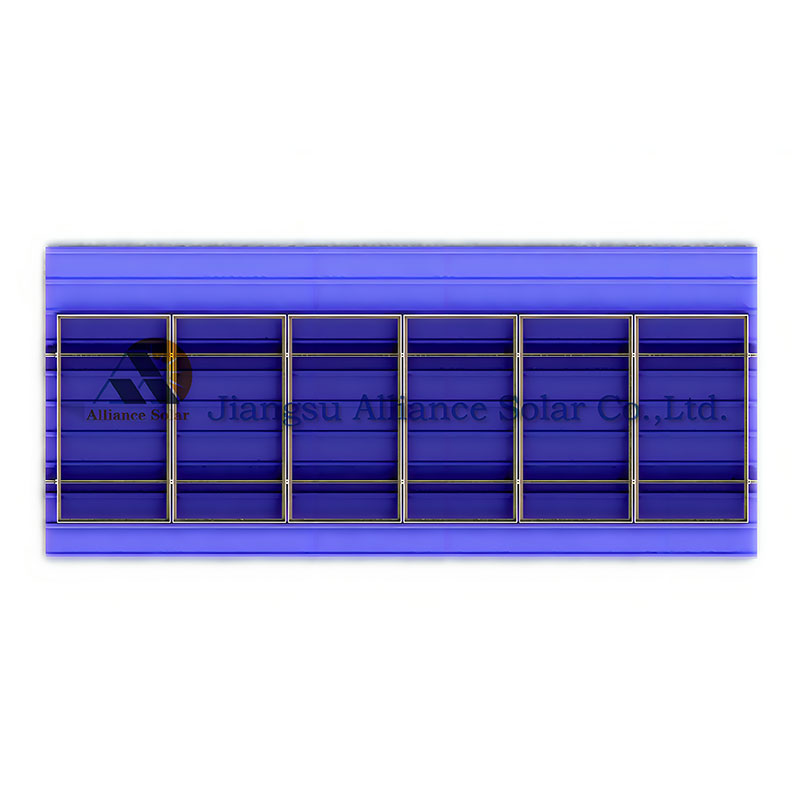

Maintaining industry-leading engineering accuracy in solar mounting systems is essential for ensuring structural stability, installation efficiency, and long-term system performance. In modern photovoltaic projects, even minor deviations in design or manufacturing can lead to installation delays, reduced efficiency, or long-term reliability issues. At Alliance Solar, engineering accuracy is treated as a core capability rather than a single production step. Through advanced design methods, precision manufacturing, strict quality control, and continuous collaboration with customers, Alliance Solar delivers solar mounting solutions that meet the highest international standards and perform reliably across diverse global environments. The process begins with precise engineering design and calculation. Every solar mounting project starts with a detailed assessment of site conditions, including wind load, snow load, seismic requirements, roof structure, and panel layout. Using advanced design tools and standardized engineering formulas, Alliance Solar’s technical team develops optimized mounting solutions that balance strength, safety, and material efficiency. Accurate load calculations ensure that every bracket, rail, and connection point performs exactly as required, avoiding over-design while maintaining full structural integrity. This engineering accuracy lays the foundation for safe and cost-effective solar installations.

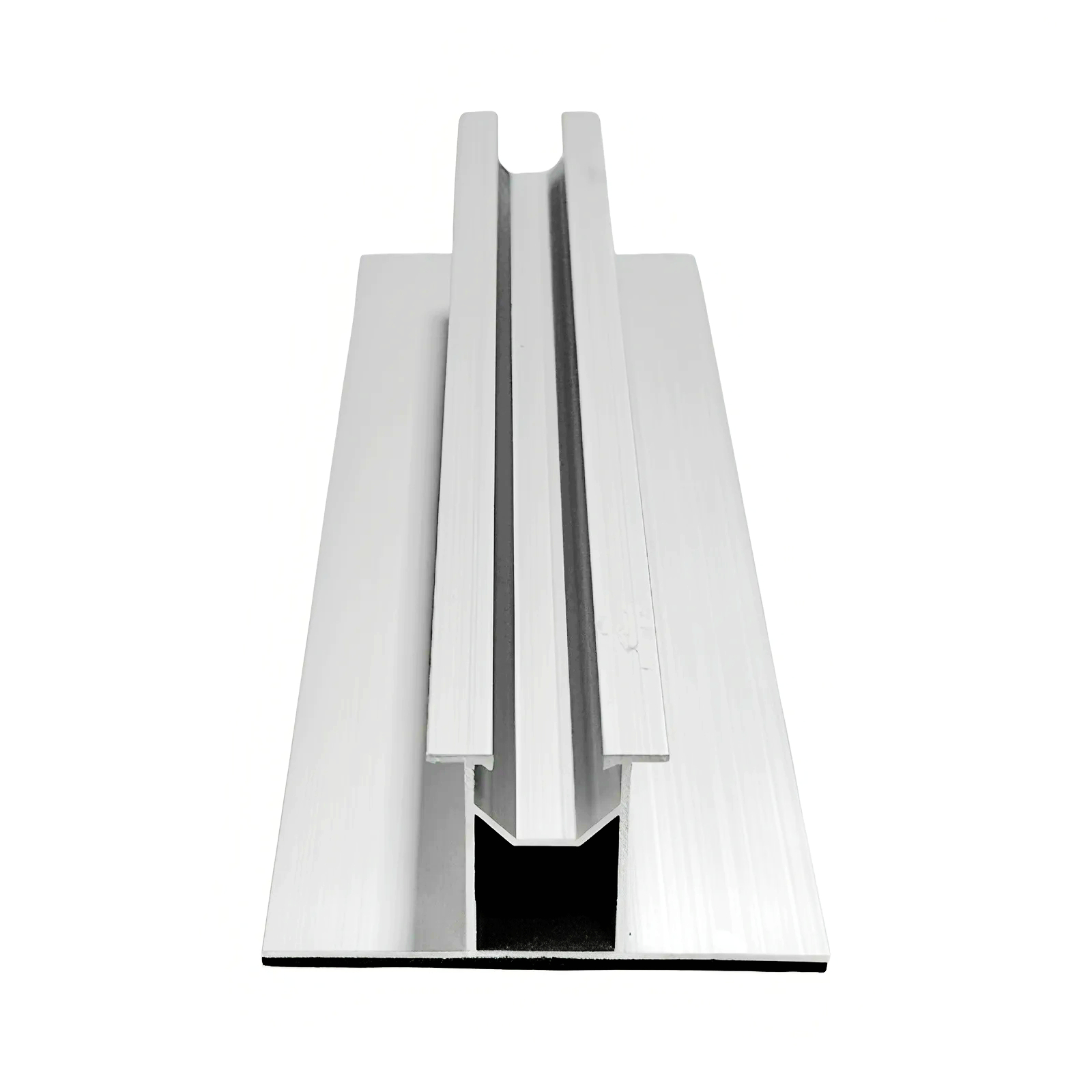

Material selection is another critical factor in maintaining precision. Alliance Solar uses high-grade aluminum alloys and hot-dip galvanized steel that meet strict mechanical and chemical specifications. Consistent material quality ensures uniform strength, corrosion resistance, and dimensional stability across all components. By working closely with certified raw material suppliers, Alliance Solar minimizes variations that could affect machining accuracy or long-term performance. Stable material properties allow engineering designs to be accurately translated into physical products without deviation. Precision manufacturing plays a central role in achieving engineering accuracy. Alliance Solar operates 15 advanced production lines equipped with modern CNC machining, precision cutting, punching, and forming equipment. These technologies enable tight tolerance control and consistent dimensions across large production volumes. Each component is manufactured according to exact design specifications, ensuring that parts fit perfectly during installation. High-precision processing reduces the need for on-site adjustments, minimizes installation errors, and improves overall project efficiency.

Quality control is integrated throughout the entire production process to maintain accuracy at every stage. From incoming raw material inspection to in-process checks and final product testing, Alliance Solar follows a strict quality management system certified under ISO9001 standards. Dimensional checks, load tests, and surface quality inspections are conducted to verify that each component meets design and performance requirements. By identifying and correcting potential issues early, Alliance Solar eliminates deviations that could impact system performance or installation timelines. Standardization combined with customization is another key strategy. While standardized components ensure consistency and repeatable accuracy, Alliance Solar also offers OEM and ODM solutions tailored to specific project requirements. Custom designs are carefully reviewed and validated by experienced engineers before production begins. Prototyping and sample testing allow customers to confirm fit, function, and performance in advance. This approach ensures that customized solutions maintain the same high level of engineering precision as standard products.

Engineering accuracy is further reinforced through close communication with customers and EPC partners. Alliance Solar works collaboratively with clients to understand project requirements, installation methods, and local regulations. Feedback from installation sites is continuously incorporated into design improvements and process optimization. This real-world feedback loop helps refine tolerances, improve ease of installation, and enhance overall system performance, ensuring that engineering accuracy translates into practical success on-site. Another important factor is continuous improvement and technological upgrading. Alliance Solar invests regularly in new equipment, advanced production techniques, and staff training to keep pace with evolving industry standards. Engineers and technicians receive ongoing technical training to improve their skills and understanding of global solar mounting requirements. This commitment to innovation ensures that engineering accuracy remains consistent even as product designs and market demands evolve.

Finally, global certification and compliance validate Alliance Solar’s engineering accuracy. Products certified under ISO9001 and TUV standards demonstrate adherence to international quality, safety, and performance requirements. These certifications provide customers with confidence that Alliance Solar’s mounting systems meet strict engineering criteria and are suitable for long-term use in international solar projects. In conclusion, maintaining industry-leading engineering accuracy in solar mounting systems requires a comprehensive and disciplined approach. Through precise design, high-quality materials, advanced manufacturing, rigorous quality control, customized engineering solutions, and continuous improvement, Alliance Solar delivers mounting structures that perform reliably across global markets. This unwavering focus on engineering accuracy ensures safe installation, long-term durability, and maximum value for customers, reinforcing Alliance Solar’s position as a trusted partner in the global solar industry.

English

English