How Solar Mounting Bracket Parts Improve System Stability and Lifespan

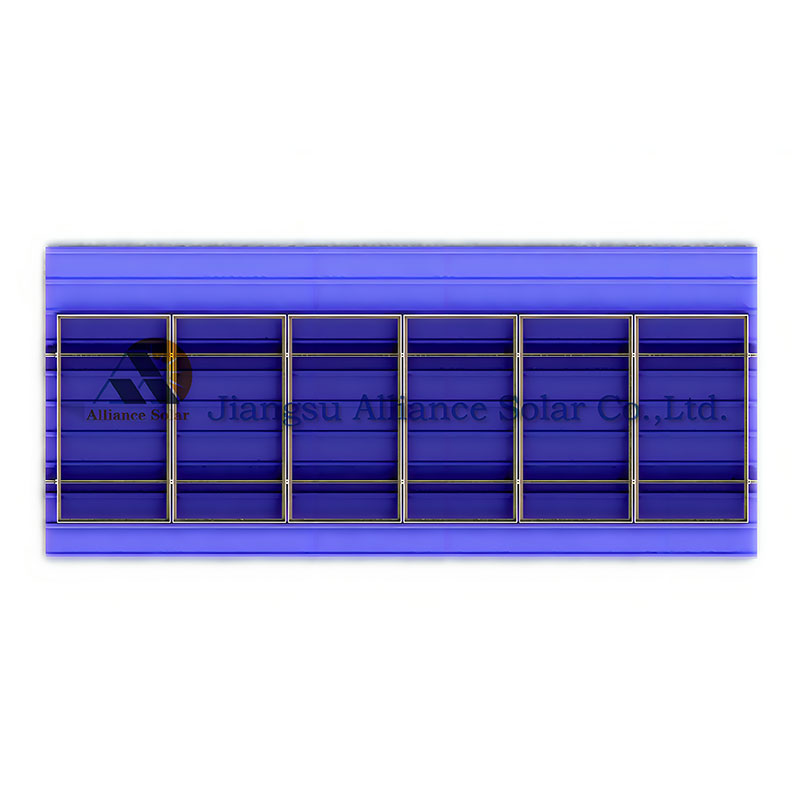

Solar mounting bracket parts play a fundamental role in ensuring the long-term durability, performance, and safety of photovoltaic (PV) systems. While solar panels typically get most of the attention, it is the supporting structure—the brackets, clamps, rails, and connectors—that keeps the entire array securely fixed and functioning effectively under various environmental conditions. High-quality mounting components are essential for preventing mechanical stress, improving structural stability, and ultimately extending the lifespan of both the panels and the power station. As global solar installations expand rapidly, the reliability of mounting bracket parts becomes even more critical for maintaining long-term energy generation efficiency.

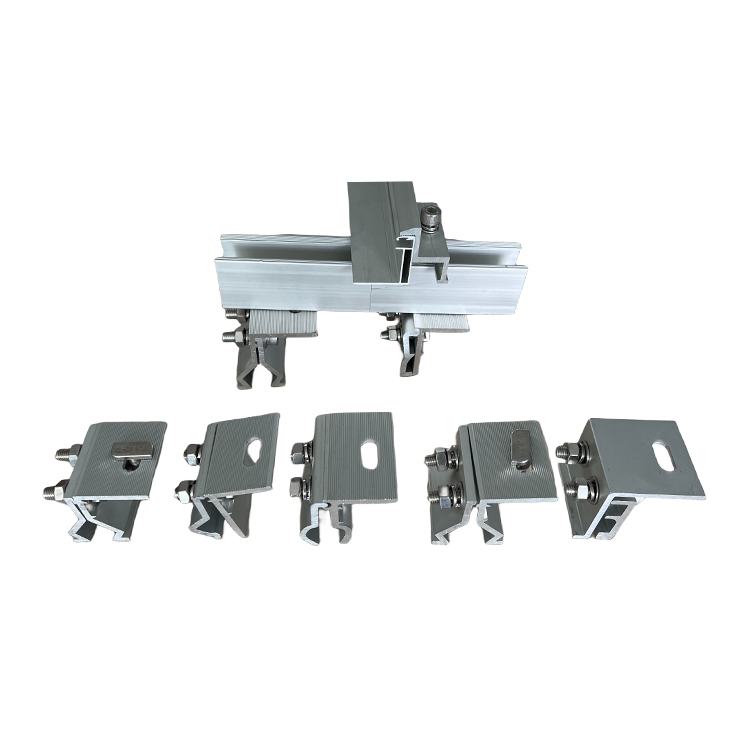

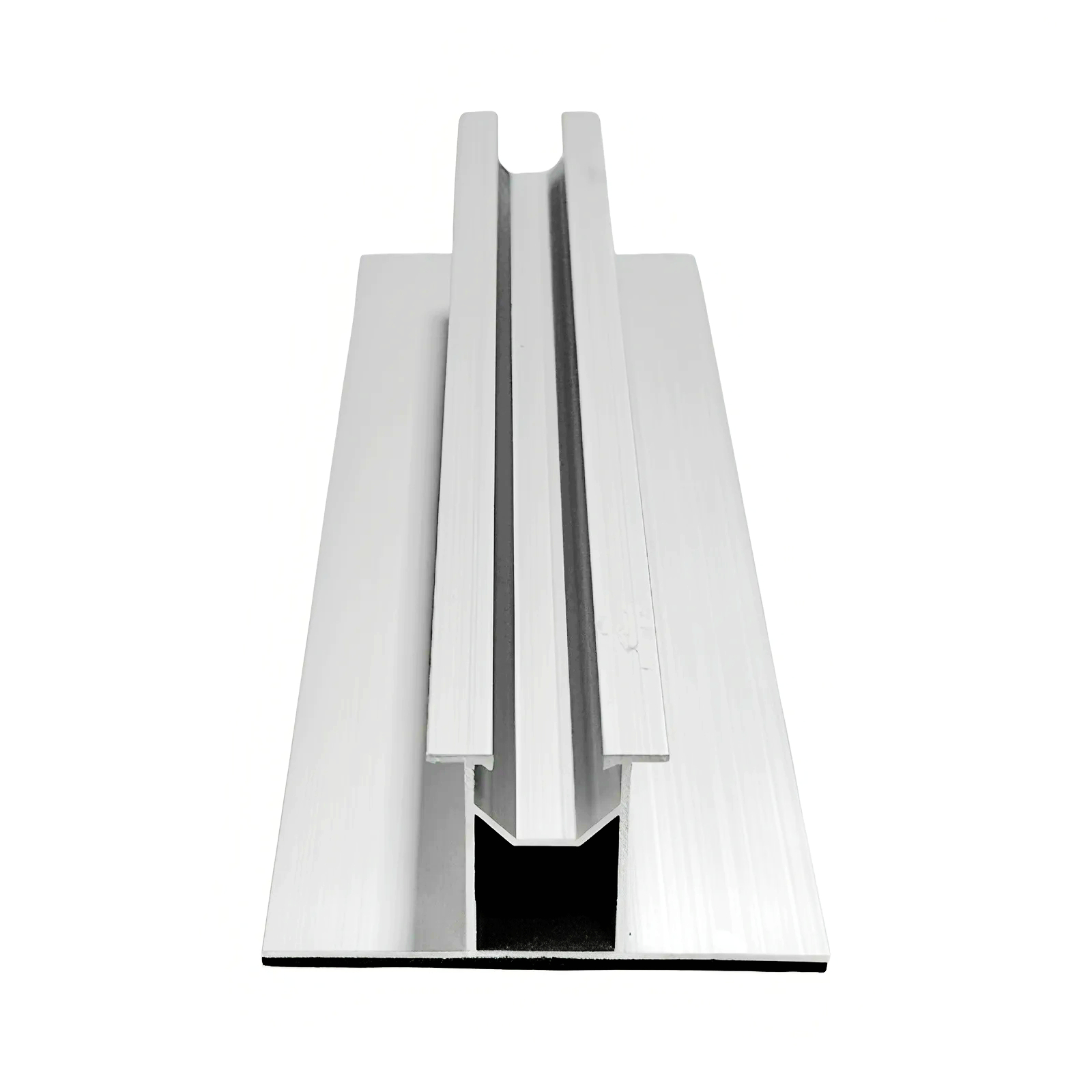

The first way mounting bracket parts enhance system stability is through strong mechanical support. Solar panels are constantly exposed to wind loads, snow loads, temperature changes, and vibrations. Without a solid mounting framework, panels can shift, crack, or even detach over time. Well-engineered bracket parts distribute weight evenly and anchor the panels firmly to the roof or ground, minimizing movement and vibration. The precision and material strength of these parts determine how well the entire structure can resist these natural forces. High-strength aluminum and steel components, such as those produced by Alliance Solar, ensure maximum mechanical stability while keeping the structure lightweight.

Another important factor that contributes to long-term system performance is corrosion resistance. Solar power stations typically operate for 25 years or more, and throughout this lifetime, mounting parts must withstand rain, humidity, UV exposure, and in some regions, salt mist conditions. Inferior materials can rust, weaken, or deform, compromising the integrity of the installation. Advanced surface treatments and high-grade alloys prevent this degradation, ensuring the mounting systems continue to perform in harsh environments. By choosing corrosion-resistant bracket parts, project owners significantly reduce maintenance requirements and avoid costly structural failures.

Precision in part design and manufacturing also plays a key role in extending system lifespan. Even small inaccuracies in brackets or rails can lead to misalignment during installation, causing uneven pressure on the solar panels. Over time, this can result in micro-cracks, loose connections, and reduced energy output. Alliance Solar’s focus on precision machining and strict quality control standards guarantees that each part fits perfectly, ensuring smooth installation and secure long-term operation. Consistency in measurements and tolerances also shortens installation time, reducing the potential for errors caused by installers having to adjust or modify components on-site. Flexibility and adaptability of bracket parts further improve system stability. Different rooftops, terrains, and project requirements demand customized solutions. Adjustable clamps, variable-angle brackets, and modular rail systems make it easier to create stable structures even on uneven or complex surfaces. A well-designed mounting system should provide flexibility without compromising strength. As the global solar market diversifies, these adaptable bracket solutions help ensure that installations remain durable across different climates and structural conditions.

Compatibility with various panel types is another important advantage of high-quality mounting bracket parts. As panel sizes, thicknesses, and technologies evolve, so must the supporting components. Properly designed clamps and brackets ensure uniform pressure distribution and prevent damage to panel frames or glass surfaces. This compatibility helps maintain optimal energy generation while protecting the investment made in high-performance modules. A reliable mounting system must support the panels securely while also allowing room for thermal expansion, preventing long-term stress build-up.

Safety is also significantly enhanced by well-designed mounting components. A strong and stable structure reduces the risk of accidents during installation and throughout the system’s lifetime. For commercial and large-scale solar projects, meeting international standards such as ISO9001 and TUV certification is essential to guarantee safety compliance. Alliance Solar’s bracket parts undergo strict testing to ensure they meet the mechanical strength and safety requirements demanded by global markets. A secure mounting system not only protects equipment but also safeguards technicians and property in surrounding areas.

Finally, solar mounting bracket parts contribute to longer system lifespan by simplifying maintenance and ensuring long-term reliability. Systems that are properly supported experience fewer mechanical issues and require fewer interventions over their lifetime. When maintenance is needed, standardized and well-designed parts make it easier to replace components without disrupting the entire array. Reduced maintenance translates to lower operating costs, making solar installations more economically attractive for investors and project owners.

In conclusion, solar mounting bracket parts are far more than simple structural accessories—they are the backbone of every reliable PV installation. Their role in supporting mechanical stability, resisting corrosion, ensuring structural precision, and protecting the panels directly affects the performance and lifespan of the entire solar energy system. By choosing high-quality components designed for durability and adaptability, such as those from Alliance Solar, project developers ensure their systems operate safely and efficiently for decades. As the global demand for renewable energy continues to grow, investing in superior mounting bracket parts becomes an essential step in achieving long-term success in solar power generation.

English

English