Choosing the Right Solar Panel Brackets for Different Roof Types

Choosing the right solar panel brackets for different roof types is one of the most important decisions in designing a safe, efficient, and long-lasting photovoltaic system. While solar panels are designed to convert sunlight into electricity, it is the mounting structure that determines how securely those panels are fixed to a building. Each roof type has its own characteristics, load-bearing capacity, and installation challenges. Selecting the proper bracket system not only improves structural stability but also increases the overall performance and lifespan of the solar installation.

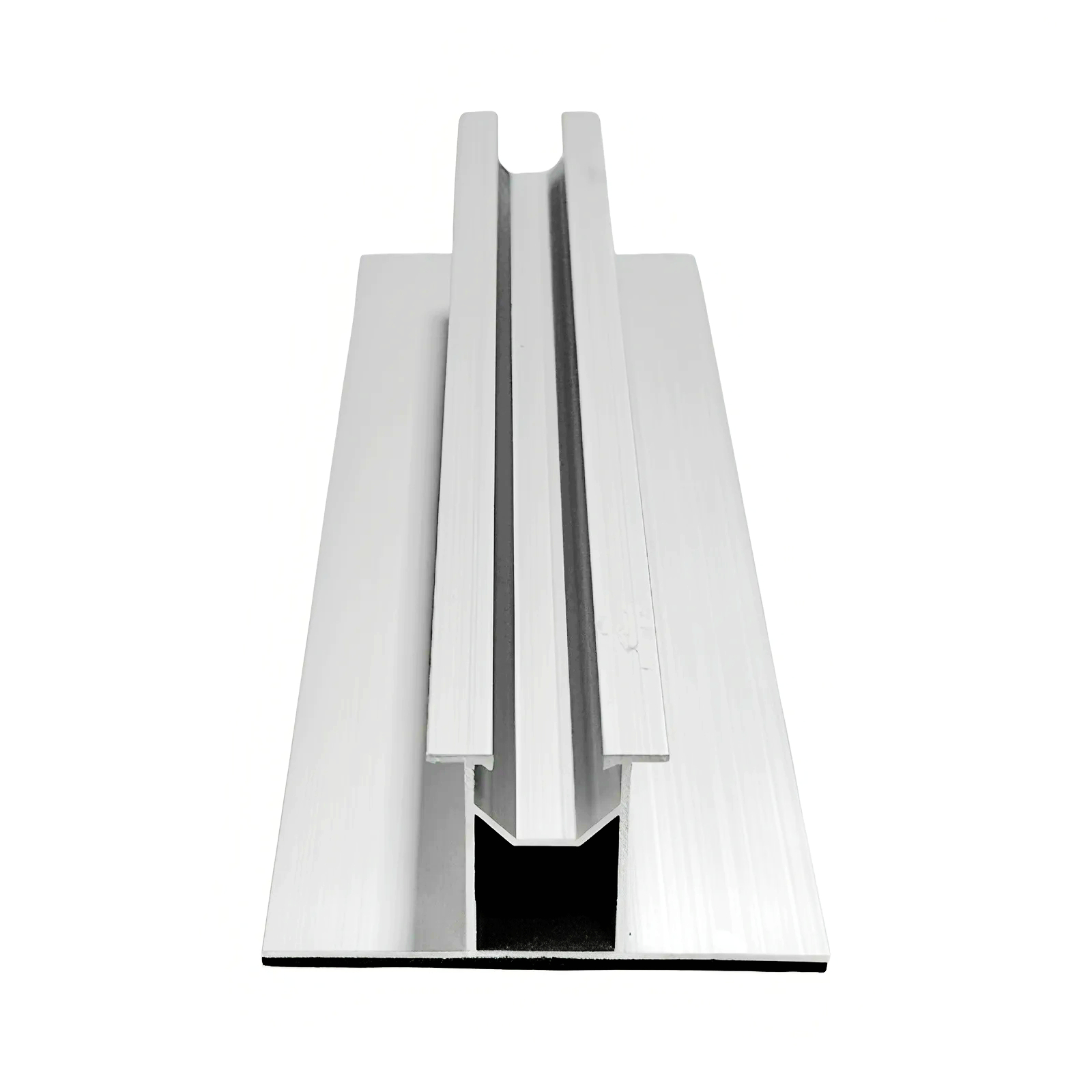

For metal roofs, lightweight and corrosion-resistant solar brackets are essential. Metal roofs are commonly used in industrial buildings, warehouses, and commercial facilities. They offer a smooth, durable surface but can expand and contract significantly due to temperature changes. Specially designed clamp systems that attach directly to standing seam or corrugated metal surfaces help avoid roof damage while ensuring a strong, stable hold. Aluminum alloy brackets are an ideal solution for these applications because of their light weight and excellent resistance to rust. With precision-engineered components, solar panels can be securely mounted without penetrating the roof surface, helping to preserve the roof’s waterproof integrity. Tile roofs present a different set of challenges. Clay, concrete, or ceramic tiles are more fragile than metal, and improper installation can easily cause cracks or leaks. For tile roofs, specialized hooks and adjustable brackets are used to anchor the system to the underlying structure rather than directly onto the tiles themselves. This design reduces the risk of breaking tiles while still providing solid support for the panels. It is important that these hooks and rails are customized to match the profile and shape of the tiles. A well-designed solar mounting system for tile roofs minimizes disruption to the existing structure and allows water to flow naturally, maintaining both safety and aesthetics.

Flat roofs, commonly seen in commercial and industrial buildings, require a different type of bracket solution, usually in the form of adjustable tripod or ballasted mounting systems. Flat-roof brackets are designed to set panels at an optimized tilt angle for maximum sun exposure. Instead of drilling into the roof surface, many systems use weight-based support blocks to hold the structure in place. This non-penetrating method helps prevent leakage and structural damage while providing excellent stability. For buildings in areas with strong winds, these systems are engineered with additional reinforcements to ensure that the panels remain secure in extreme weather conditions. Concrete roofs and rooftops with limited load capacity also require careful bracket selection. These surfaces are strong and durable, but excessive drilling or heavy systems may weaken the structure over time. Precision-engineered base plates and spread-footing designs help distribute weight evenly across the surface, reducing concentrated pressure points. By using high-strength aluminum and steel in a carefully calculated structure, mounting brackets can deliver strong support while keeping overall system weight to a minimum. This balance between strength and lightness is essential for protecting both the roof and the solar installation.

Another key factor in choosing the right solar brackets is the environmental condition of the installation site. Coastal areas with high salt levels, industrial zones with air pollution, and regions with heavy snowfall or sandstorms all place extra stress on mounting systems. Brackets must be treated with anti-corrosion coatings, anodized aluminum, or hot-dip galvanized steel to ensure long-term resistance to environmental damage. High-quality surface finishing protects the mounting structure and prevents deterioration over time, helping the system maintain its structural integrity for more than 25 years. Compatibility with solar panel types is equally important. Panels vary in size, thickness, and frame style depending on the manufacturer and technology. High-quality brackets must be designed to support a wide range of modules while providing firm clamping force without damaging the panel frame. Precision manufacturing and strict tolerance control ensure that each bracket fits perfectly, reducing installation time and ensuring consistent pressure distribution. This prevents micro-damage and protects the long-term performance of the solar panels.

At Alliance Solar, great importance is placed on offering customized solutions for every roof type. With over 15 advanced production lines and the capacity to support up to 1.5GW annually, Alliance Solar works closely with global customers to provide both standard and OEM/ODM mounting systems. All products meet ISO9001 quality standards and TUV international certifications, ensuring compliance with regional and international requirements. By analyzing roof structure, climate conditions, and customer goals, the engineering team develops tailored mounting solutions that perfectly match each project. In conclusion, choosing the right solar panel brackets is not just a technical decision; it is a long-term investment choice. The proper bracket system protects the roof, supports the panels, improves efficiency, and ensures system durability for decades. Whether the project is on a metal, tile, flat, or concrete roof, selecting high-quality, precision-engineered components is essential for achieving maximum performance and safety. With Alliance Solar’s expertise, innovation, and dedication to quality, customers around the world can confidently build stable and efficient solar power systems suited to their specific roofing needs.

English

English