How Our Production Lines Ensuring Efficient, High-Volume Solar Mounting Manufacturing

Efficient, high-volume manufacturing is the backbone of reliable solar mounting supply, especially as global photovoltaic projects continue to grow in scale and complexity. At Alliance Solar, our production lines are designed to deliver consistent quality, fast turnaround, and scalable output without compromising engineering accuracy. Through advanced equipment, streamlined workflows, and strict quality management, we ensure that every mounting system meets international standards while supporting large-volume project demands across global markets. Our manufacturing efficiency begins with a well-planned production layout. Alliance Solar operates within an 18,000-square-meter facility equipped with 15 dedicated production lines. Each line is organized to handle specific processes such as cutting, punching, forming, machining, surface treatment, and assembly. This clear division of processes eliminates bottlenecks and allows materials to move smoothly from one stage to the next. By optimizing production flow, we reduce idle time and maximize daily output capacity.

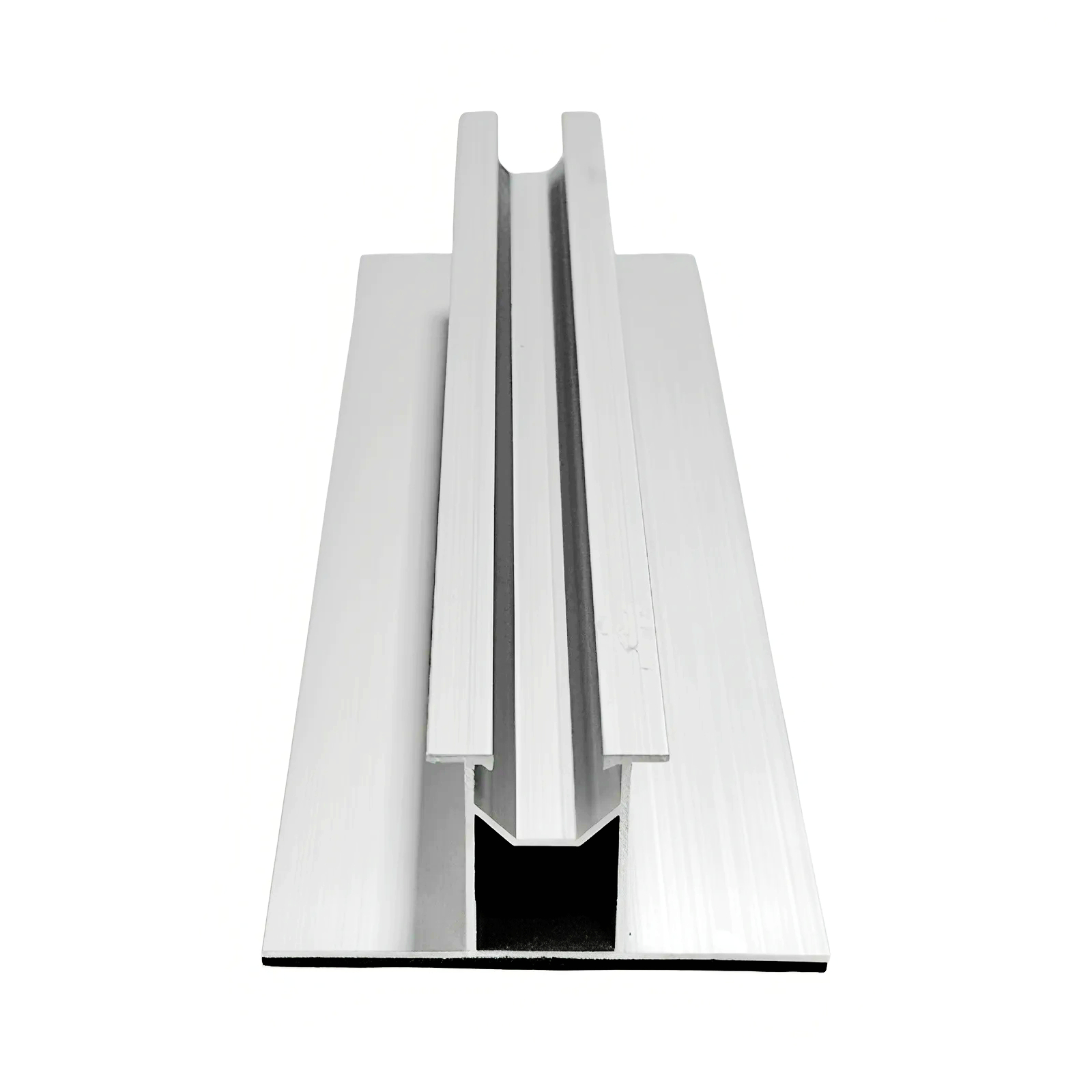

Automation and precision equipment play a key role in achieving high-volume consistency. Our production lines utilize CNC machining centers, high-speed punching machines, precision cutting equipment, and automated forming systems. These machines ensure tight tolerance control and repeatable accuracy across large production batches. Automation minimizes human error while increasing processing speed, allowing Alliance Solar to produce large quantities of mounting components with uniform quality. Standardization is another important factor in manufacturing efficiency. While we offer extensive OEM and ODM customization, many core components—such as rails, clamps, and fasteners—are produced using standardized dimensions and connection methods. This standardization allows components to be manufactured in parallel across multiple lines, increasing output capacity while maintaining compatibility across product systems. When custom designs are required, standardized processes are adapted quickly without disrupting production schedules.

Material management also supports high-volume manufacturing. Alliance Solar maintains stable long-term partnerships with qualified raw material suppliers, ensuring consistent availability of aluminum profiles and steel materials that meet ISO9001 and TUV standards. Strategic material stocking and inventory control reduce the risk of supply interruptions and allow rapid response to urgent or large-scale orders. This supply stability is critical for meeting tight international project deadlines. Quality control is fully integrated into every production line to ensure efficiency without sacrificing reliability. Instead of relying solely on final inspection, quality checks are embedded at key production stages. Dimensional accuracy, surface quality, and mechanical integrity are inspected continuously during manufacturing. By identifying issues early, we prevent rework and production delays, keeping output stable and predictable while ensuring all products meet strict quality requirements.

Workforce expertise further strengthens production performance. Alliance Solar employs skilled technicians and production specialists who are trained to operate advanced machinery and follow standardized procedures. Continuous training programs help workers improve efficiency, safety awareness, and quality control skills. Experienced operators can quickly identify abnormalities and adjust processes in real time, ensuring smooth production even during high-volume manufacturing periods. Flexible production scheduling allows Alliance Solar to handle both standard and customized orders efficiently. Our production lines are designed to switch between product types and specifications with minimal setup time. This flexibility enables us to manufacture customized OEM/ODM solutions alongside standard products without slowing down overall output. As a result, customers receive tailored solutions on schedule, even for complex international projects.

Packaging and pre-assembly are also optimized within our production lines to support efficient installation and logistics. Components can be pre-assembled or packaged according to project sequence, reducing on-site labor and simplifying installation. Smart packaging design protects products during long-distance transportation while enabling faster unloading and identification at the job site. This integration of manufacturing and logistics adds further efficiency to the overall project timeline. In conclusion, Alliance Solar’s production lines are engineered to deliver efficiency, scalability, and reliability at every stage of manufacturing. Through advanced equipment, streamlined workflows, standardized processes, skilled personnel, and integrated quality control, we ensure consistent high-volume output without compromising precision or performance. This manufacturing strength allows Alliance Solar to support large global solar projects, meet tight delivery schedules, and provide customers with dependable mounting solutions that power renewable energy systems around the world.

English

English